charpy impact test specimen location|charpy impact test formula : purchase In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the .

Resultado da A story about friendship, love, and independence, being a minority youngster. Based on Maria Navarro Skarangers debut novel.

{plog:ftitle_list}

WEBAll of BetBoom’s registered users have access to their customer care 24 hours a day, 7 days a week. You can reach the agents via phone at +44 7520641752. If you prefer a .

The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load [10]. This test consists of striking a suitable specimen with a .A Charpy Impact Test involves striking a notched metal sample with a swinging pendulum. The amount of energy absorbed by the sample during fracture is then measured. This provides us with invaluable data about the material’s .

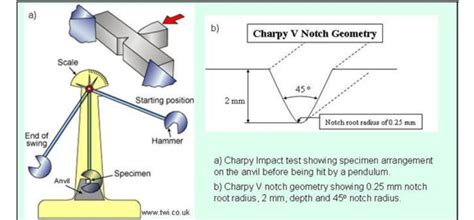

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specificationsIn carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine. The specimen is supported at each end as shown in Figure 2 and the pendulum strikes the .In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the .

In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. The notch in the middle has a V-shaped .The Charpy V-notch (CVN) technique is most commonly used. Both of these tests use a notched sample of a defined cross-section. We use notch toughness for these dynamic loading conditions and when a notch is present. The location . The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .

5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce .The standard Charpy Impact Test specimen consist of a bar of metal, or other material, 55x10x10mm having a notch machined across one of the larger dimensions. V-notch: 2mm deep, with 45° angle and 0.25mm radius along the . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the . This paper presents the results of the Charpy V-Notch (CVN) impact test for the ST, TL, TS, LS, LT, 45°, and SL directions in API 5L X52 pipelines with electric-resistance-welded (ERW) and .

4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces. . 7.3 Location of test pieces. 7.4 Interpretation of test results. Bibliography. FiguresCharpy V-notch impact test is used to determine the V-notch toughness of a metallic material according to the absorbed amount of energy for fracturing. . It acts only as a sufficient stress concentration to force the failure at that location in the specimen. Charpy data for parent materials is sometimes provided by the material supplier. The .

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .The previous article looked at the method of Charpy-V impact testing and the results that can be determined from carrying out a test. This next part looks at the impact testing of welds and some of the factors that affect the transition temperature such as composition and microstructure. . PD5500 App D. location of Charpy specimens in weld . The notched face of the impact test specimen is chosen either parallel or perpendicular to the surface of the test piece, and the specimen can be cut at various depths below the surface of the test piece, with the location of the notch measured relative to the center of the weld or relative to the fusion-joint line. . Testing Charpy specimens . The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar. These specifications have a very tight tolerance because the shape and size of the notch can have a significant effect on the results of the test.

Charpy V-notch (CVN) impact testing of the welded steel product. A required toughness level is commonly expressed for a particular test temperature (which may be different from the lowest anticipated service temperature) at which a minimum CVN impact energy value (KV min), shall be achieved.The approximate relationship between the CVN energy .This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally in the Charpy impact testing machine. The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample.

влагомер wile 65 цена

Download scientific diagram | Charpy-V impact test specimens: (a) dimension; (b) notch locations with red vertical lines representing the locations: WM (weld metal), FL (fusion line) + 1 mm, FL .

charpy v notch sample size

A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. The standard test .

Charpy impact testing (also known as a Charpy V-Notch test) is a valuable method to determine the amount of energy a material absorbs during fracture. The test is performed when a pendulum head is dropped from a specified . Charpy V specimen and V notch location (L-T orientation of Charpy specimens) Bojana ZEČEVIĆ et al. / Procedia Structural Integrity 42 (2022) 1475–1482 1477 Author name / Structural Integrity Procedia 00 (2019) 000–000 3 Two typical diagrams, force vs. time, and energy vs. time, obtained by instrumented impact testing are .Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.

влагомер алиэкспресс

Hazra et al. [20] have evaluated the forge effect of DDFW for high nitrogen steels and have concluded tensile and Charpy impact test results indicated that the joint strength is decreased with an . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be:Specimen size: Specimens are 80 x 10mm by thickness. The specimens can be either notched or unnotched. Data: Impact energy is expressed in joules. Impact strength is calculated by dividing impact energy in joules by the area under the notch. A higher number indicates a tougher material. **Please note that this test description is intentionally . The NIST Charpy Machine Verification Program is introducing certified low-energy and high-energy Charpy specimens to be tested at 21 °C instead of -40 °C.These new Standard Reference Materials can be ordered from the NIST SRM store (https://shop.nist.gov/) using the following numbers:Low-energy: SRM 2561 (NIST-Verification, 21 °C, 8 mm strikers),

The “standard” notch used in the Charpy impact test is the 2 mm deep V-notch with a 0.25 mm root radius, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm. Charpy Impact Test. In a Charpy test, a notched specimen is struck by a pendulum hammer swinging from a known height. The energy absorbed by the specimen during fracture is calculated by the difference in the pendulum’s height before and after impact. This energy absorption measures material toughness.The quantity measured is the energy absorbed in breaking the specimen by a single blow. The ideal impact test would be one in which all the energy of a blow is transmitted to the test specimen. Charpy impact test specimens are cut from metal samples, and a V-notch is placed in the center. Charpy impact testing can be performed at ambient and .ASTM E23 and ISO 148-1 define test methods for Charpy impact testing of notched-bar metallic specimens. ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy absorbed by the notched specimen when impacted by a swinging pendulum.

Question: You were determining the Charpy impact strength for Your polyethylene material. You used hammer with 5J energy and standard impact test specimen (see slide 23) with notch (notch depth 1,2 mm). 64 % of the hammer energy was consumed for breaking the sample; what was the impact toughness of Your PE-material?

charpy impact test sample dimensions

webRule34 - for lovely fans of it. New high-quality Rule 34 - videos and photos by famous artists. If it exists, there's a porn about it! Now it's about femboy.

charpy impact test specimen location|charpy impact test formula